Structure Fabrication

Lyka laser has completed 10,00,000 sq. ft. of Structural Fabrication work on time for different types of projects for industries of Agriculture, Engineering, Food, Plastic and Textile.

We can discuss your requirements for structural fabrication today.

Please call us +91 8200495181

In the World demanding Quickness Structural Engineering has been proving itself a must. Structural Engineers are professionals who are specialized in designing the best structures considering the Safety Standards.

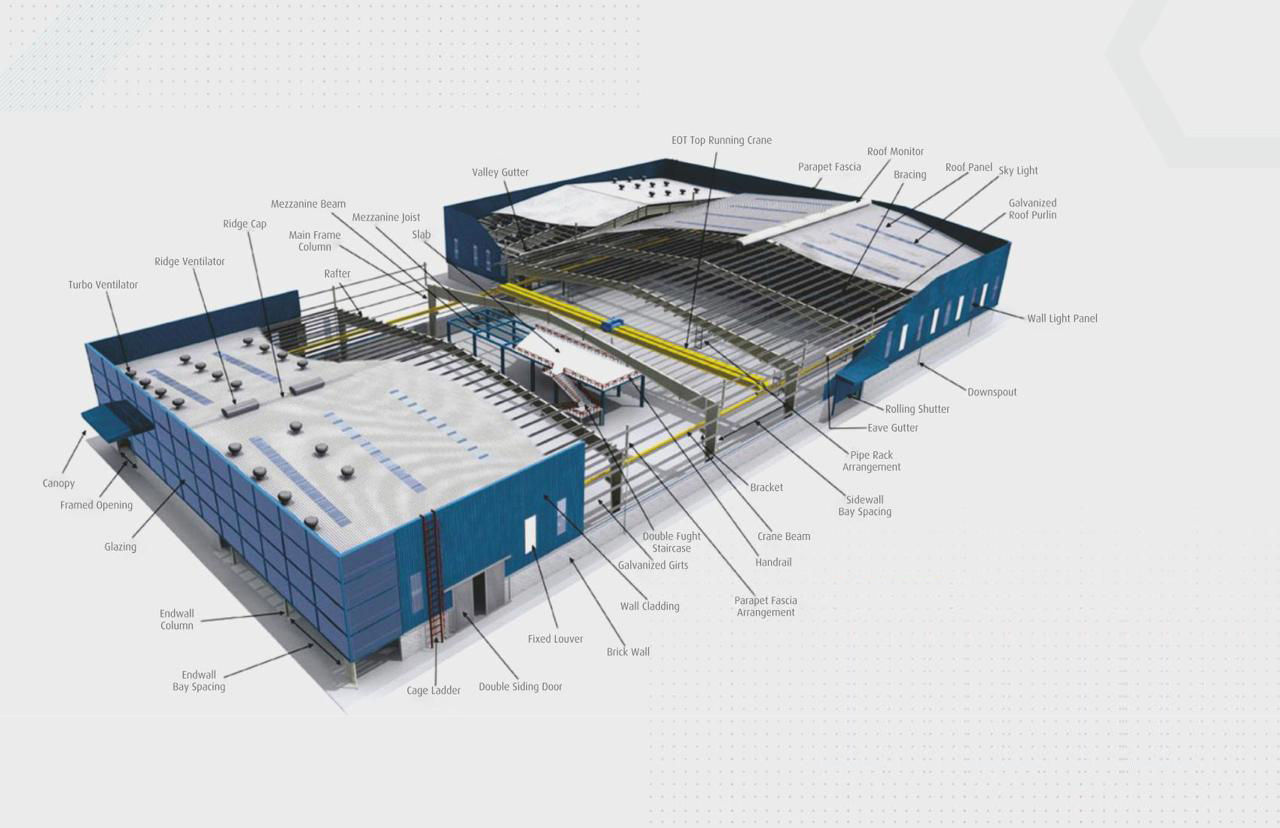

Structural Fabrication is a kind of Metal Fabrication. Temporary, Mobile and Permanent structures can be established by Structural Fabrication.

You must have noticed the structured metal fabrication in Theaters, Malls, Stadiums, etc. But, now almost every sector is being the consumer of Structural Fabrication.

Do you know why Structural Fabrication is spreading more dramatically than any rumor? But, out of hundred reasons, the one is the same which has brought you here on our page.

What exactly is Structural Fabrication?

Being simple, Structural Fabrication is nothing but, designing and building Structures. Structuring involves processes like cutting, bending, melting, welding, and shaping the metals.

Structure Engineer, Designer or Fabricator draws the best Possible and Safe structure according to requirements. Then the Fabricator starts working on it.

Applications of Structural Fabrication

Implementation of Structural Fabrication is causing the old construction methods to fade away day by day. Structural Fabrication can be used to build any designed structure.

- Structural Fabrication is used to build Residential Buildings to Skyscrapers

- Industrial sheds, Industrial Storage, Warehouses, and Industrial sheds are established by Structuring.

- Commercial Buildings, Service Centers are constructed by Structural Fabrication.

- To some degree, Structural Fabrication is applied while building Gyms, Malls and Theaters.

Why Structural Fabrication is widely used?

In Structural Fabrication, Metals are used to build up the structures. The major part of the structures contains various types of steel. Mild steel and Structural steel are used widely for a broad range of purposes.

- Structural Fabrication can give you durable, corrosion neutral, convenient and safer buildings and structures.

- Unlike old structures, you can move, replace and modify the Fabricated Structures anytime.

- Mild Steel is more ductile even than normal steel. It can wear any shape while Structural Steel is highly strong, stiff and durable compared to other options available.

- Building a structure consumes significantly less time compared to conventional construction methods.

- Using insulation methods, you can control the inner temperature of Structures.

- Generally, metals used in Structural Fabrication are the least harmful to our environment and manufacturing of those metals and materials is also preferred to be environment friendly.

- And, I know that nobody can neglect the beauty of well-finished Structures.

How we make it happen?

Once you confirm the Drawing/Blueprint of Structure, we at Lyka Laser Tech pour our work and skills upon the raw materials to manifest the drawing in the real world.

Our teams handle the following processes to make the miraculous work happen with immense accuracy:

Drawing/Blueprint

Cutting

Lyka Laser Tech has most renowned “DNE BYSTRONIC” Laser Cutting machine which provide smooth and cost effective services. Our most advance machine has unique advantage like laser output pulse frequency 32000 Hz, which gives more butter quality than others. Our machine cutting bed size is 6.5 meter length and 2.5 meter in width with smooth cutting. We provide accuracy and thickness of Mild steel up to 45 mm, Stainless steel up to 40 mm, Aluminium up to 30 mm and Copper up to 10 mm.

Raw materials such as metal sheet, pipes are cut into pieces as the Blueprint demands. Special instruments are used to cut different types of raw materials.

Bending

Bending is the second stage of laser cutting. Lyka Laser Tech is using latest CNC hydraulic servo hybrid press break machine of Hindustan hydraulic having capacity of 200 tons. Hindustan hydraulic machine which is developed for high flexibility & low setup time with advantage of 4300 mm bending length.

We are using heavy bending machines to bend the metals into the pieces. Bending provides shape to the metals.

Welding

Welding is the most important in fabrication industry. We have experienced & well certified welders in fabrication and offer Mig Tig Spot & Stud welding. Lyka Laser Tech follow WPS, PQRS Welding process & procedure. We also implanted din EN 15085 & IRI Standard.

Welding assembles the parts permanently. We generally use welding techniques such as Shielded Metal Arc Welding (SMAW), Flux Core Arc Welding (FCAW), MIG Welding, Gas Tungsten Arc Welding (GTAW).

Finishing Touch

The process of giving finishing is the Key to bring Smoothness and Shining to the structure.

Painting

Various types of painting can be applied to make the structural materials look attractive, Homogeneous, Insulated, corrosion-resistant, or heat resistant.

What we’ve got for you?

At Lyka Laser Tech we can work from head to toe to make your structures ready. We furnish pre-designing and pre-construction work mind-blowingly.

Establishing Industrial sheds and Industrial structures is our expertise.

We are well specialized to perform the following tasks:

- To give you the best Blueprint ideation for your Structures

- To give you budget and time-saving strategies

- To finish the work within a decided time frame

- To suggest you the best material based on the application

- At last, we know your time is precious. Once you finalize the contract and allot the space to work on, we will drive it to the end independently.

Why would you choose US?

To be honest, there are lots of Fabricators to choose from. We’ve proudly highlighted some rare qualities of ours:

- Our professional teams are trained and well experienced to work on heavy projects. By understanding your needs and budget, we offer suitable products and services.

- We play with every type of structural fabrication from small Industrial sheds to complicated Industrial structures.

- Don’t worry. We give true suggestions to choose the best materials and designs.

- We have mastered our skill on both Budget-Focused and Quality-Focused projects.

- We give the validity of our structures based on the material and method you select.

Metals used in Structural Fabrication

Structural Fabrication is done using various metals and alloys based on the requirements. Metals including Copper, Aluminum, Steel and their alloys can be used. But among these all, Steel is used majorly due to its highly corrosion-fighting nature and astonishingly attractive look.

But as per structural needs, there are different types of steel categorized according to Carbon level in it. A higher carbon level in steel delivers higher strength.

Structural Steel

Structural steel is the most durable steel. It contains a higher level of Carbon above 1% by weightage. It is the main alloy used excessively in Structural Fabrication.

Structural Steel can withstand high loads with surprising stability being highly corrosive.

Mild Steel (MS)

It is also called Low Carbon Steel because it is mild compared to other steels. It carries carbon weightage by 0.2% to 0.6%. It has superb bending and melting properties than other types of steel.

About US

Structural Fabrication is done using various metals and alloys based on the requirements. Metals including Copper, Aluminum, Steel and their alloys can be used. But among these all, Steel is used majorly due to its highly corrosion-fighting nature and Everyone has dreams. And our dream is to build your dreams. Starting from really low-level projects, we are at a significant destination now. All our progress and success belong to you.

We are proficient at Work rather than Marketing skills which is the rarest characteristic nowadays.

d astonishingly attractive look.

But as per structural needs, there are different types of steel categorized according to Carbon level in it. A higher carbon level in steel delivers higher strength.

Contact US

To have us for developing your structures contact us now.

We believe in the quote by Albert Einstein: “Once you stop learning You start dying.” We want to always keep learning and growing. We are hungry for honest feedback which help us improve ourselves and our services.

Industries Served

Structural Steel Fabricators/Heavy Construction

- Bridge Builders

- High Rise Buildings

- Hospital

- Industrial Construction

- Commercial Construction

- Electrical Power Plants

- Water Treatment Plants

- Metal Building Manufacturers

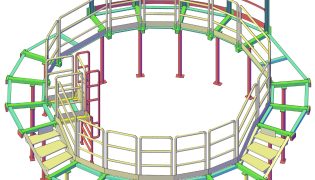

- Amusement Park Attractions

- Transmission & Distributions